-1709882920.jpg)

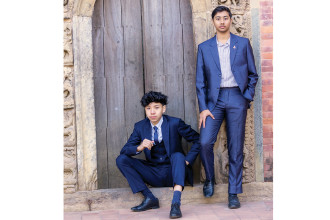

Milan Bohara, CEO & Sashi Kiran Thapa, CFO

Kleanit Upcyclers

Plastic is an inevitable element used in most households and workplaces; however, a lot of it goes to waste. But to prove that plastic is not just waste but a resource, Milan Bohara, a computer science graduate, and Sashi Kiran Thapa, a business management graduate, co-founded Kleanit Upcyclers.

“It was during our time at Truman State University in the United States during talks we realised that we were both problem solvers and we shared similarities in our thought processes,” says Thapa. Bohara adds that both loved travelling and during one trip to California they noticed a sign which stated ‘This road is made from plastic.’ “This intrigued us a lot and after returning from the trip we started doing some research on plastic and realised the limitless possibilities of plastic as a resource,” shares Bohara, adding, “We decided to return to Nepal in 2021 and start Kleanit Upcyclers the very same year.”

Kleanit Upcyclers is a problem-solving company that works on plastic waste using efficient technology. The co-founders collaborate with companies like Blue Waste to Value to collect scrap resources. They also source scrap from Prashanna Plastic Balaju and other informal scrap resourcers building a wide network in waste resources and management. “We use the melting technology to convert these scraps into useful lumber,” says Thapa, further explaining that they do not burn the plastic scraps but rather melt and reshape them. Just the way that potters mould clay, they mould plastic to create lumbers, benches, machines, flower pots, glasses, bracelets and notebook covers.

“While studying abroad we came across various technologies that helped promote sustainable development,” mentions Bohara. Identifying this limitless possibility, they wish to replicate and innovate similar technologies in Nepal to help achieve sustainable development.

Though they have gained recognition for their work, both share that the journey has not been easy. Initially, they used to research and try out various experiments using the locally available resources at home. “After the initial phase of experiments, our major concern was availing the required machines, however, thanks to Mahabir Pun we have been provided space at the National Innovation Centre and funding to make our own machines,” shares Bohara, adding that they are still based at the NIC and continuing with their research and development. He candidly reveals that in the initial period of their research when they did not have money, some team members deserted them. “However, we persisted because we believed in our idea.”

It was after two years of rigorous research they were ready to market their products but again finding the market was a hurdle as they had no market connection. “Also, it was difficult to blend our products with the daily lifestyle of people as people interpret plastic as waste and despite recycling, they are hesitant to purchase it,” says Bohara.

But perseverance is key, and the duo were untired in their determination to meet with success. They met Nabin Bikash Maharjan, Co-founder and CEO of Blue Waste to Value, who helped them gain some market traction. They installed around 12 two-storey benches made from plastic waste in Kupondole, Lalitpur. Similarly, they installed other benches in Kamalpokhari, Chandragiri, Budhanilkantha and Dang. Moreover, their flower pots have been used as tokens of love at various events. “It gives us immense pleasure to say that through all this perseverance, research, and innovation we have been able to convert 25,000 kg of plastic waste into useful products till date. This certainly is an achievement for us as we walk towards the path of sustainability,” exclaims Bohara.

Thapa acknowledges the importance of customer gratification in their business. “We constantly aim to deliver quality products that are affordable and our delivery is always on time,” he says, adding they are able to achieve this with the help of technology. “We research various innovative technologies being introduced abroad to help facilitate efficiency as customer satisfaction is paramount for us along with sustainability,” he adds.

During the conversation, both co-founders spoke of some memorable moments during their work. “Initially, during our research, the lumbers were getting stuck in the machine and one day I used excessive spray on the machines. To my surprise, the lumbers came out exactly the way they should. I call this my Eureka moment,” shares Bohara. Thapa adds that as a non-engineering student, when he saw the first prototype of their machine it gave him immense joy. “I will probably never forget that moment,” he states.

Currently, both are looking into ways to expand their business. They aim to scale the business and continue exploring plastics. “We aim to research different types of plastics now. We want to figure out the homogeneous and heterogeneous plastics and research on various other products that we can make from these,” shares Thapa. “Innovation is something that we are going to continue and explore as in our field innovation has no boundaries,” concludes Bohara.